Buy janome bias binding foot. How to use the optional JANOME and FAMILY sewing machine feet (Sewing and Cutting)

How to use additional legs for sewing machines JANOME and FAMILY Concealed zipper foot This unique foot will help you sew invisible zippers quickly and easily. Job Description: 1. Open the zipper. 2. Place the right half of the zipper facing the front of the right side of the garment. 3. Fold the teeth to the right and lower the foot so that the teeth are in the groove of the foot to the right of the needle. Sew up to the end of the cut mark. 4. Place the left half of the zipper facing the front of the left side of the garment. Make sure that both parts of the product are level. 5. Fold the teeth to the left and lower the foot so that the teeth are in the groove to the left of the needle. Sew up to the end of the cut mark. 6. Place the standard foot on the machine and sew below the zipper. Blindstitch foot. The blind hem foot is suitable for discreet hemming of heavy to medium weight fabrics. Description of work: 1. Turn the edge of the product inward by the width of the hem. 2. Now unfold the fold so that the edge of the fabric protrudes 1 cm. 3. Place the fabric under the foot with the wrong side up and the fold along the guide as shown. 4. Adjust the needle so that it fits exactly into the fold of the fabric, catching 1 to 2 strands of fabric. Pintuck foot. Description of work: Using the pintuck foot and twin needles 2 mm You can quickly make pinches on thin fabrics. Straight stitch length 2-2.5mm. The pintuck is created when sewing with a twin needle, while the fabric is fed with a pinch that goes into the groove on the bottom of the foot. Insert the pintuck into the notch on the bottom of the foot to guide the next fold. Binding foot Binding piping is sufficient in a simple way to give the edges of the garment an even and neat look. For this it is necessary to cut a bias tape 24 mm wide. Description of work: 1. Cut the beginning of the bias tape diagonally. 2. Insert the sharp corner of the tape into the cochlea and pull it out behind the foot. 3. Adjust the binding device or move the needle so that the needle enters the tape 1-1.5 mm from the folded edge of the folded tape. 4. Place the cut edge of the edging piece between the folded tape in the cutout of the edging device. The bias tape will automatically loop around the part while sewing. Hemming foot 2mm. Hemming prevents fabric edges from fraying and creates a beautiful, durable seam thanks to the foot. This foot can be used to sew the edges of scarves, shawls, clothing and home decor made from lightweight materials without first pressing the edge. Job description: 1. Select a straight stitch. 2. Cut a small piece of fabric at an angle from the side to be cut. 3. Thread the cut corner of the fabric into the hem hole on the foot. 4. Lower the foot and sew several stitches while drawing both threads to the back. In this case, the cut of the fabric should turn up and enter the hole for the hem on the foot. 5. Continue sewing, moving the fabric evenly forward. Teflon foot. This foot is made of a special polymer for sewing on materials that are prone to difficult movement with the metal foot - vinyl, faux and Genuine Leather, nubuck, etc. During operation, it will slide over the surface of the fabric, performing any stitch. Smocking foot. With this foot, you can sew on fabrics or customize laces with a gathered effect. At the same time, you can also increase or decrease the fit by adjusting the thread tension. It is better to increase the stitch length / 3.5 - 4.5 /. The operation with this foot will tighten the fabric. Topstitch foot. Select a straight stitch with a center needle position. Unfold the fabric and make sure the foot moves along the seam line. Lay the next line parallel to the previous one. The use of the foot is very convenient when wasting products. The foot is also indispensable for adding decorative stitches along the seam. Piping foot. You can use a ready-made edging, or make it yourself from your material. Job description: 1. Place the finished piping along the seam line on the right side of the garment. 2. Lay the second piece face to face on top. 3. Place the fabric and piping under the foot so that the piping goes through the groove on underside paws. 4. Stitch with a straight stitch. The groove on the underside of the foot acts as a guide for the piping while sewing.

1. Open the zipper.

2. Place the right half of the zipper facing the front of the right side of the garment.

3. Fold the teeth to the right and lower the foot so that the teeth are in the groove of the foot to the right of the needle. Sew up to the end of the cut mark.

4. Place the left half of the zipper facing the front of the left side of the garment. Make sure that both parts of the product are level.

5. Fold the teeth to the left and lower the foot so that the teeth are in the groove to the left of the needle. Sew up to the end of the cut mark.

6. Place the standard foot on the machine and sew below the zipper.

Blindstitch foot.

The blind hem foot is suitable for discreet hemming of heavy to medium weight fabrics.

Set of two feet for 5 and 7 pintucks. Description of work:

Set of two feet for 5 and 7 pintucks.

Work description:

1. Select a straight stitch.

2. Cut a small piece of fabric at an angle from the side to be cut.

3. Thread the cut corner of the fabric into the hem hole on the foot.

4. Lower the foot and sew several stitches while drawing both threads to the back. In this case, the cut of the fabric should turn up and enter the hole for the hem on the foot.

5. Continue sewing, moving the fabric evenly forward.

Teflon foot.

Work description:

1. Set the zig-zag width on the machine to match the distance between the button holes.

2. Switch off the lower conveyor or install the darning plate.

3. Place the button on the fabric according to the markings so that the button is fixed / Madeira temporary fabric adhesive can hold the button during work /.

4. Slowly lower the needle bar so that the needle enters the left hole of the button. When leveling the holes in the button, sew a slow stitch so that the needle will enter the right hole in the button.

5. For buttons with 4 holes: Transfer the needle to the other pair of holes and follow the same procedure.

Satin stitch foot.

Choose decorative, finishing or zig-zag stitching.

Choose decorative, finishing or zig-zag stitching.

The stitch length should not exceed 0.5mm.

Loosen the upper thread tension.

The foot is designed for sewing curly stitches, monograms, appliqués, and can be used for quilting.

Blindstitch foot.

The blind hem foot is suitable for discreet hemming of heavy to medium weight fabrics. Now there is no need to hem the product by hand.

The blind hem foot is suitable for discreet hemming of heavy to medium weight fabrics. Now there is no need to hem the product by hand.

> Job Description:

1. Fold the hem of the garment inward by the hem width.

2. Now unfold the fold so that the edge of the fabric protrudes 1 cm.

3. Place the fabric under the foot with the wrong side up and the fold along the guide as shown.

4. Adjust the needle so that it fits exactly into the fold of the fabric, catching 1 to 2 strands of fabric.

The zipper foot is universal.

Attach the foot depending on the sewing left or right side lightning.

Attach the foot depending on the sewing left or right side lightning.

Lower the foot at the beginning of the zipper so that the stitch lines up along the fold of the zipper teeth.

Set of 2 hemming feet - 4mm and 6mm.

With these feet you can hem on medium-thick fabrics, such as napkins, curtains, linen, etc.

With these feet you can hem on medium-thick fabrics, such as napkins, curtains, linen, etc.

Work description:

1. Select a straight stitch.

2. Press the beginning of the seam to be seam 4mm or 6mm wide, depending on the size of the presser foot installed.

3. Place the folded edge under the foot and sew several stitches.

4. Leave the needle in the fabric to hold it in place. Raise the foot and insert the edge of the fabric into the curler of the foot.

5. Lower the foot and continue sewing while holding and guiding the edge of the fabric.

6. Make sure the fabric does not go under the right half of the foot.

Roller foot.

The roller foot is ideal for sewing difficult fabrics: leather, nubuck, knitted fabrics and others, while preventing sticking and the formation of creases and folds.

The roller foot is ideal for sewing difficult fabrics: leather, nubuck, knitted fabrics and others, while preventing sticking and the formation of creases and folds.

Choose a straight stitch or any decorative stitch.

Piping foot.

You can use a ready-made edging, or make it yourself from your material.

You can use a ready-made edging, or make it yourself from your material.

Work description:

1. Place the finished piping along the seam line on the right side of the garment.

2. Lay the second piece face to face on top.

3. Place the fabric and piping under the foot so that the piping goes through the groove on the underside of the foot.

4. Stitch with a straight stitch. The groove on the underside of the foot acts as a guide for the piping while sewing.

Sewing foot.

It is easy to sew braid, sequin thread, elastic band with this foot. The foot easily guides the tape through the hole in the front of the foot.

Overlock foot.

The overlock foot is designed for overcasting. A thin tab on the foot prevents the seam edge from curling up.

The overlock foot is designed for overcasting. A thin tab on the foot prevents the seam edge from curling up.

With an overlock or zig-zag stitch, set the zig-zag width to 5, turn the wheel by hand to make sure the needle does not hit the foot.

Hello again!

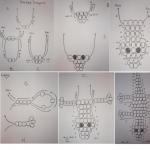

Today I propose to get acquainted with the special feet for sewing machines, which are used for edging.

At this time, the market for accessories for sewing machines offers its consumers several types of binding feet. Here are the most popular ones to match many sewing machines.

- This is the binder foot. It is also called a device for edging or a foot for edging a cut with a bias tape. It is equipped with a funnel for folding the bias tape and guiding it around the edge of the fabric.

- This is a binding foot with a ruler.

As you can see, these legs differ sharply from each other in appearance.

Sometimes they, however, like the legs of "the same suit" or, as they say, acorns of the same oak, may differ from each other in the way they are attached to the sewing machine.

So, before purchasing such accessories, you need to make sure that they really fit your sewing machine.

It is best to make a purchase in a company store that sells sewing machines and accessories to them, exactly that brand as your sewing machine. Well, if it is very far to the company store, you need to conduct a market research, consult with the seller, double-check his information and only then buy legs for edging.

The legs differ from each other and in the way of making edging.

How do I use the Binding foot?

We begin by attaching this foot to the sewing machine.

The bias binding device only works with one binding size. And it makes a finished edging with a width of 6 mm. Consequently, the "blank" for the inlay should be 24 mm wide, folded with the wrong side inward, and with the fold ironed exactly in the middle.

and with the tip cut obliquely for convenience.

The length of the bias tape should be 5-10 centimeters more than the cut on which the edging is actually performed. This additional section is needed to work out the settings of the foot on it.

The prepared binding can be inserted into the binder foot in several ways.

1st method.

Starting to move the sharp corner of the inlay along the right rounded wall of the funnel, we gradually move deeper and deeper into the funnel.

In the slots located on the same right wall of the funnel, you can gently push the tape along the wall of the device with a needle or pin until it comes out of the funnel.

2nd way.

In this way, the binding is threaded into the funnel a little faster.

In the open inlay, near its top, at a short distance from the edge, pass a needle and thread through the fabric.

And we fix there, made at the end of the thread to be threaded with a knot.

And now we start the thread from left to right, between the layers of the edges of the funnel bent inward and under the main part of the foot.

Guiding the thread along the right rounded wall of the funnel, we tighten it, and together with it we stretch the inlay along all the details of the device.

We have nothing to worry about. As you can see, the edging device will do the trick.

And when the first millimeters of the folded inlay come out of the funnel, all this splendor must be fastened by simply dipping a needle into the fabric.

On the "fresh", just purchased foot for edging cuts with a bias tape, everything is set, which is called by default.

And when the first centimeters of the formed inlay went under the main part of the foot, you can already clearly see that the needle of the sewing machine stands relative to the front of the foot with a funnel so that when performing a straight stitch, it will be laid exactly in the middle of the edging, along the already folded and a bias tape wrapped around the cut.

And this is not gut! Firstly, such edging will be wrong and ugly. And secondly, and so not too wide, wrapped inward cuts of the inlay may not be captured by the stitching.

If the "ability" of your sewing machine allows you to move the needle position the desired distance in left side, then you need to do it.

Well, those sewing lovers whose sewing machine does not have such capabilities should, using the screw located on the foot,

adjust the moving part of the foot so that the needle seams closer to the left edge of the tape.

And since such a foot uses only one size of the binding, then having set it up once, it is possible that you will never return to this procedure again.

This is where we needed those extra centimeters of inlay for tuning.

Well, it's time to insert a piece of fabric between the layers of the already folded inlay. And to make it more convenient to do this, when performing the last stitch, leave the needle in the material, and raise the foot.

It remains only on the left side, exactly in the gap between the edges of the device wrapped in a funnel and close to the foot, carefully insert the cut of the edging fabric.

And all you can lay a line.

But there is still a third way to start edging the slice. When both the bias tape and the cut to be processed by it are simultaneously inserted into the "labyrinths" of the foot.

To do this, we connect the edge of the cut to be processed and the sharp corner of the inlay to each other by passing a needle and thread through them and fixing it with a knot.

And now, as in the second method described above in the article, we wind the thread between the layers of the edges of the funnel bent inward and under the main part of the foot.

This is of course the most quick way thread everything, as you need to and immediately start working. But this requires careful attention to ensure that all the details fall into their designated places. The edges of the inlay should fit along the rounded wall of the funnel, and the cut of the fabric should pass between the edges of the funnel bent on the other side inward.

If everything falls into place, as it should, then the cuts of the inlay will immediately be wrapped around the cut of fabric

All that remains is to set the position of the needle or adjust it relative to the needle, the details of the foot, and you can immediately start sewing.

In order for the inlay to lay down smoothly and beautifully around the cut being processed, all the time you need to hold the inlay together and the fabric cut nested to its fold. You need to keep them in the direction of the conditional line coming out of the funnel of the device.

Here is a cut of fabric, edged with a bias tape, it looks like this from the front side of the part,

but from the seamy side.

The bias binding foot works great with a one-piece binding! cut along an oblique strip of fabric.

Poorly, if not disgusting, this foot works with an inlay stitched from separate strips. The presser foot makes a finished binding with a width of only 6 mm. And even if the seam connecting the parts of the bias tape passed through the foot, and the edges of the tape are bent inward in this place as it should, you still look at finished product such a connection would be disgusting.

Therefore, you need to either harvest a whole strip of fabric for the bias tape, or sew the tape to the cut.

The bulky, cumbersome Binding Foot works great on straight or not very curved cuts. To very concave and very convex cuts, for example, to the sometimes very steep transition between the neck cut between the back and the shelf, it is better to attach the inlay

How do I use the Ruled Binding Foot?

Now let's get acquainted with another foot - the binding foot with a ruler. It also makes the edging of the cut, like the previous foot, but unlike the first one, it can make a edging with a width of 5 to 20 mm on the cut being processed!

Contrary to the previous foot, this one does not fold the tape inwards. And it works with the finished inlay (with the edges ironed to the middle).

Therefore, before undertaking edging with a foot and a ruler, you need to prepare the required width of the inlay, in one of the ways described and 5 centimeters longer than the cut being processed.

And since we already know the width of the inlay, which we will attach to the product, now it is possible on the foot, using the front adjusting screw, to set the size of the groove to the size of the inlay.

Attach the foot to the sewing machine.

Insert the end of the prepared inlay into the grooves on the foot,

and in the gap between the layers of the tape and the grooves of the foot we insert a cut of fabric.

We make the first puncture of the material with a needle and look at the needle.

The sewing machine stitch should securely and beautifully fasten the edging material around the cut to be sewn. It should pass along the inlay - neither in the center nor along its outer edge, but at a distance of 1.5 - 2 - 2.5 mm from the inner edge attached to the product.

Therefore, those whose needle moves horizontally to the left should set the desired needle position to the right.

Well, those lovers of sewing at home, whose machine does not make such "movements", with the help of the adjusting screw located on the back - the main part of the foot, must adjust the position of the front parts of the foot relative to the needle.

The Ruled Binding Foot does more than just bias tape. You can insert into it: a tape, and a braid, and a piping and process cuts with these materials from shedding.

Features of working with these edging materials can be found in the article

The wider the edging (from 1 cm and wider), the easier it is for the presser foot with a ruler to work with a binding made up of separately cut strips, and the more accurately the finished edging is obtained on the product.

The ruled foot, like the Binding foot, is also very clumsy and therefore works just as poorly on very curved cuts.

To skillfully handle these two paws, you must first, as they say, fill your hand and follow all the individual rules for working with each of them. And then, in the end, both of them will produce the same result, neatly made edging.

And there are also edging feet that attach to overlocks. Will be needed get to know them too.

Edging the cuts with the special edging feet is just one way to attach the binding to the cut to be cut.

So let's get acquainted

Good luck! Best regards, Milla Sidelnikova!