Women's shirt pattern is the best in blogs. How to build a pattern for a woman's shirt? Nightshirt

Hello.

In this article, we will learn how to build a shirt structure.

Shirt-cut clothes are primarily distinguished by the parameters and configuration of the armholes. The size of the shirt armhole is larger than the size of the armhole of the basic design of the dress, and the configuration of the shirt armhole is wider and deeper. Therefore, the details of the shirt pattern - the back and the shelf also differ in their parameters and configuration.

There are two ways to build a shirt structure: apply structural modeling basic pattern dresses, or use the developed technique to build the design of the shirt. In this article, we will look at the second option.

To build a shirt pattern, we need the following measurements:

Name of measurements and legend | cm |

|---|---|

Semi-girth of the neck (US) | |

Semi-girth of the chest (Cg) | 40,5 |

Waist girth (St) | |

Half hip (Sat) | 44,8 |

Back length to waist (dts) | |

Breast height (Bg) | |

Shoulder length (dp) | |

Product length (Di) |

In this cutting technique, we will consider two shirt silhouettes: semi-adjacent and straight... A shirt of a semi-adjacent silhouette assumes the presence of chest and waist darts, while the product is quite free and dynamic. The shirt of a straight silhouette has no darts, and the product itself is more free. As a result, the cut of these two silhouettes differs not only in the additions to a free fit, but also in some construction constructions. To construct a pattern for a shirt in a straight and semi-adjacent silhouette, we will use the following allowances for free fit:

The increase along the chest line between the details of the structure is distributed as follows:

We will prepare a blank sheet of paper, the length of which is 5-10 cm longer than the measurement of the length of the product.

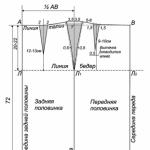

Drawing grid

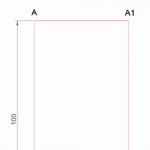

Product length and width... Having departed 5 cm from the top edge of a sheet of paper, draw a rectangle AA 1 H 1 H, where the sides AH and A 1 H 1 are equal to the measurement of the length of the product, and the sides AA 1 and HH 1 are equal to the measurement of the half-girth of the chest with an increase in free fitting (AH = A 1 H 1 = Di = 68cm; AA 1 = HH 1 = Cr + CO = 40.5 + 5.5 = 46cm). note, in this example, I used an increase for a semi-adjacent silhouette, if you draw a straight silhouette, then do not forget to substitute the corresponding increases for free fitting in the formulas (see the table above).

Armhole depth... From point A downward in a straight line, set aside 1/3 measurements of the half-girth of the chest + CO (see the table of increments) and put the point G (segment AG = 1 / 3Cg + CO = 40.5: 3 + 9 = 22.5 cm). From point Г to the right we draw a horizontal line to the intersection with the segment А 1 Н 1, the point of intersection is designated Г 1.

Back width... From point G we set aside 1/3 measurements of the half-girth of the chest + CO (see the table of the distribution of the increase along the chest line) and get the point G 2 (segment GG 2 = 1 / 3Cg + CO = 40.5: 3 + 3cm = 16.5cm) ... From the point Г 2 upwards, construct a perpendicular to the intersection with the side AA 1, the point of intersection is designated P.

Armhole width... From G 2 to the right, set aside 1/4 measurements of the half-girth of the chest + CO (see the table of distribution of the increase along the chest line) and mark the point G 3 (G 2 G 3 = 1 / 4Cg + CO = 40.5 / 4 + 0.5 = 10.6cm). From the point Г 3 upwards we draw a perpendicular to the intersection with the side AA 1, and the point of intersection we denote by П 1.

Waistline... From point A downwards, we postpone the measurement of the length of the back to the waist and put the point T (AT = Dts = 40cm). From point T we draw a horizontal line to the intersection with side A 1 H 1 and designate the point of intersection T 1.

Thigh line... From point T downwards, set aside half the measurement of the length of the back to the waist and put point B (TB = 1 / 2Dts = 40: 2 = 20cm). Draw a horizontal line from point B to the intersection with the segment A 1 H 1, mark the intersection point B 1.

Side line... Divide the segment Г 2 Г 3 in half, the intersection point is designated Г 4 (Г 2 Г 4 = Г 4 Г 3), and down from this point we lower the perpendicular to the intersection with the bottom lines, the intersection point is designated Н 2, and the points of intersection with the waist lines and hips - T 2 and B 2.

Auxiliary points of the armhole... We divide the segments G 2 P and G 3 P 1 into three equal parts, the lower points of division will be designated P 2 and P 3 (see Fig.).

Back construction

Back neck cut... From point A to the right, set aside 1/3 measurements of the half-girth of the neck + 0.5 cm (for all silhouettes) and get point A2 (AA 2 = 1 / 3Cw + CO = 15: 3 + 0.5 = 5.5cm). Up from point A 2, set aside 3cm (for all silhouettes) and mark point A 3 (A 2 A 3 = 3cm). We will draw the line of the neck with a smooth line, observing the right angle at point A.

Shoulder section of the back... From point P downwards, we put off 3cm (for all silhouettes) and put point P 4 (PP 4 = 3cm). Now we connect points A 3 and P4, and on the resulting straight line from point A 3 we postpone the measure of the length of the arm + CO (see the table of increments) and put the point P 5 (A 3 P 5 = Dp + CO = 13 + 1.5 = 14 , 5cm).

Back armhole cut... We connect the points P 2 and G 4 with a dotted line and divide this segment in half, and from the point of dividing down we set aside 2 cm at a right angle and put the point P 6.

Let's make a cut of the armhole with a smooth concave line, connecting the points P 5, P 2, P 6 and G 4.

Back yoke... Set aside 8cm down from point A and put point K (AK = 8cm). From point K to the right, draw a horizontal line to the intersection with the line of the armhole of the back, and the point of intersection is designated K 1.

Down from the point K 1 along the armhole line, set aside 1 cm and put the point K 2 (K 1 K 2 = 1 cm). Connect point K 2 with a smooth line with the yoke line.

Building a shirt shelf in a straight silhouette

Cut of the neck of the shelf... From point G 1 upwards, set aside half the measurement of the half-girth of the chest and put a point P (G 1 P = 1 / 2Cg = 40.5: 2 = 20.3 cm). Draw a horizontal line of arbitrary length from point P to the left.

Now, from point P to the left and down, we postpone 1/3 measurements of the half-girth of the neck + 0.5 cm and mark points P 1 and P 2 (PP 1 = PP 2 = 1 / 3Cw + CO = 15: 5 + 0.5 = 5.5cm ). We connect points P 1 and P 2 with a dotted line, which we divide in half and from point P through this division point we postpone 1/3 measurements of the half-girth of the neck + 0.5 cm and get point P 3 (PP 3 = 1 / 3Cw + CO = 15: 5 + 0.5 = 5.5cm).

Let us draw a smooth line to cut the neck through points P 1, P 3 and P 2, observing a right angle at point P 2.

Shoulder cut of the shelf... Let's build an auxiliary line, connecting point P 1 with the upper division point of the segment PG 2 (see Fig.), On this line from point P 1 to the left, set the measure of the arm length + CO and put the point P 7 (P 1 P 7 = DP + CO = 13 + 2 = 15cm). Pay attention, now we are considering the construction of a straight silhouette shirt shelf, so the increase in the formula corresponds to the increase for a straight silhouette.

Shelf armhole cut... We connect the points P 3 and G 4 with a dotted line, divide this segment in half, from the point of division we lower the perpendicular 2 cm in size and mark the point P 8.

Let us draw a smooth line for the cut of the armhole, connecting the points P 7, P 3, P 8 and G 4.

This completes the construction of the shirt with a straight silhouette.

Our pattern is ready!

Constructing a shirt shelf in a semi-adjacent silhouette

Cut of the neck of the shelf... From point G 1 upwards, set aside half the measurement of the half-girth of the chest + 0.5 cm and put the point P (G 1 P = 1 / 2Cg + CO = 40.5: 2 + 0.5 = 20.8 cm). Draw a horizontal line of arbitrary length from point P to the left.

Down and to the left of point P, set aside 1/3 measurements of the half-girth of the neck + 0.5 cm and mark points P 1 and P 2 (PP 1 = PP 2 = 1 / 3Cw + CO = 15: 5 + 0.5 = 5.5cm) ... We connect points P 1 and P 2 with a dotted line, which we divide in half and from point P through this division point we postpone 1/3 measurements of the half-girth of the neck + 0.5 cm and get point P 3 (PP 3 = 13 / Cw + CO = 15: 5 + 0.5 = 5.5cm). Let us draw a smooth line to cut the neck through points P 1, P 3 and P 2, observing a right angle at point P 2.

Shoulder cut and bust dart... To the left of point P 1, set aside 4 cm and put point B (P 1 B = 4 cm), down from point B, set aside 1 cm, we get point B 1 (BB 1 = 1 cm). Let's connect points P 1 and B 1.

Add the lengths of the segments PP 1 and P 1 B (5.5 + 4 = 9.5 cm), subtract 1 cm from this sum (9.5-1 = 8.5 cm), postpone the resulting value to the left of the point G 1 and put the point G 5 (G 1 G 5 = PP 1 + P 1 B-1 = 8.5 cm). We connect points G 5 and B 1, the segment G 5 B 1 - the right side of the chest dart.

Now we will construct an auxiliary line by connecting point B with the upper division point of the segment PG 2. Upward from point Г 4, draw a vertical line to the intersection with the auxiliary line, the intersection point is designated by O.

To the right of point O, we postpone the shoulder length on the auxiliary line with an increase in free fitting minus the length of the segment P 1 B and put point B 2 (ОВ 2 = Дп + СО-Р 1 В = 13 + 1.5-4 = 10.5 cm) ... Further, from point Г 5 upwards through point В 2 we draw a segment, the length of which is equal to right side darts and get point B 3 (G 5 B 3 = G 5 B 1).

Down from the point O, set aside 3cm and put the point O 1 (OO 1 = 3cm). Connect the points O 1 and B 3 with a thin line.

From point B 3 to the left along a thin line, we postpone the length of the shoulder with an increase in free fitting minus the length of the segment P 1 B and put the point P 7 (B 3 P 7 = Dp + CO-P 1 B = 13 + 1.5-4 = 10 , 5cm).

Shelf armhole cut... We connect the points P 3 and G 4 with a dotted line, divide this segment in half, from the point of division we lower the perpendicular 2 cm in size and mark the point P 8. Let us draw a smooth line for the cut of the armhole, connecting the points P 7, P 3, P 8 and G 4.

Calculation of the solution of darts along the waist line... From the width of the product, we subtract the measurement of the waist half-girth with an increase in free fitting (AA 1 - (St + CO) = 46- (30 + 3) = 13cm), the result obtained is the sum of the solution of all darts along the waist line, where

the size of the solution of the front dart = 0.25 of the total solution of the darts (13 x 0.25 = 3.3 cm),

the size of the lateral tuck solution = 0.45 of the total solution (13 x 0.45 = 5.8 cm),

the size of the solution of the back tuck = 0.3 of the total solution (13 x 0.3 = 3.9 cm).

Determination of the width of the shirt along the hips... Now, from the measurement of the half-girth of the hips with an increase in free fitting, we subtract the width of our product (Sb + SO-AA 1 = 44.8 + 4-46 = 2.8 cm), the result obtained is the value of the expansion of the product along the line of the hips.

Side cut... From point T 2 along the waistline to the right and left, set aside half of the solution of the lateral tuck (we calculated its value a little higher) and mark the points that we connect with straight lines to point G 4.

From point B 2 along the line of the hips to the right and to the left, set aside half the size of the expansion of the product along the line of the hips and put points that we connect with smooth convex lines with the points of the solution of the lateral dart at the waist and extend these lines to the intersection with the bottom line.

Construction of a tackle dart on the back... To the right of point T, we postpone 1/3 measurements of the half-girth of the neck + 0.5 cm and put the point T 3 (TT 3 = 1 / 3Cw + CO = 15: 3 + 0.5 = 5.5). From point T 3 to the right, we postpone the value of the entire solution of the tuck of the back and get point T 4 (T 3 T 4 = 3.9 cm).

Divide the T 3 T 4 segment in half, and draw a perpendicular through the dividing point, not bringing it to the chest line 6 cm, and 12 cm to the hip line, this perpendicular is the midline of the dart. We connect points 6 and 12 with the points of the tuck solution T 3 and T 4.

Refinement of the waist line and the bottom line of the shelf... From point T 1 we put down 1 cm, the resulting point will be connected with the notch along the waist line along side cut, observing the right angle at the point 1cm. Down from the point H 1, we also set aside 1 cm and connect it with a smooth line with the point of the bottom line along the side cut, while the angle at the point 1 cm should be straight.

Building a tackle tuck on a shelf... Subtract 1.5 cm from the value of the segment G 1 G 5, postpone the resulting value to the left of the point 1 cm along the new waist line and put the point T 5 (1T 5 = G 1 G 5 -1.5 = 8.5-1.5 = 7cm ). Let's connect points T 5 and G 5.

Along the new waistline to the left of the point T 5, we postpone the size of the solution of the front dart and put the point T 6 (T 5 T 6 = 3.3 cm). Along the line Г 5 Т 5 downwards from the point Г 5 we postpone 6 cm, we connect the resulting point with Т 6.

We divide the segment T 5 T 6 in half, and from the point of division we lower the perpendicular, not bringing it to the waist line 12 cm. Now let's connect point 12 with points T 5 and T 6.

This completes the construction of the shirt design.

If the shirt model has a button fastener, then the shelf must be extended along the neckline and the bottom line by the same distance - 1.5-2 cm and draw a new cut line for the shelf. The resulting line is the half-line line, and on the middle line there are buttons on one part of the shelf and buttonholes on the second part.

Clasp sections can be processed in several ways:

Stitching bar ,

The width of which is twice the width of the half-strip, the length of the strip is equal to the length of the ledge along the half-strip line, while the upper cut of the strip repeats the cut of the neck of the ledge along the entire width of the strip.

One-piece plank ,

Its configuration is completed by extending the bottom line of the shelf by twice the width of the half-nose, and then a vertical line is drawn upward from the resulting point. The line of the neckline on the bar is drawn symmetrically to the neckline of the shelf relative to the half-line. When sewing a shirt with a one-piece strap, the strap itself is bent along the half-line to the seamy side of the product.

Supate clasp

It is a hidden clasp, buttons in such a clasp are hidden and are not visible from the front side of the product. The configuration of such a fastener is completed from a one-piece strap, extending the bottom line of the product by a length equal to twice the width of the strap. As a result, three widths of the plank are obtained along the bottom line, a vertical line is drawn up from each width. The line of the neck of the fastener is drawn symmetrically relative to the line of the first plank. Along the half-line of the shirt, the fastener is bent to the seamy side, along the next vertical line, the clasp is bent, and along the next vertical line, the fastener is folded back to the seamy side and the cut line of the shelf (on the fastener) is stitched from the seamy side of the product. The supate clasp is built on only one part of the shelf, on which the buttonholes are located, and only a one-piece strip is built on the part with buttons.

In this article I have collected the whole process of sewing a shirt, as they say from A to Z!

The author of this miracle: Elena Kucherova is a professional seamstress. So, I ask you not to praise me too much))

What the post includes:

Firstly, the easiest shirt pattern construction I know of !!!

Further: sewing, transfer of darts, video fitting, fitting, as well as many little tricks!

I wish you creative inspiration and good luck in making your plans come true !!!

Enhancements for freedom of fit for a shirt

To begin with, I decided to give the increments worthy attention. Please note that now we are talking about sewing a classic shirt from non-stretch fabric.

Actually, why do we need to increase the measurements?

People tend to move, especially such active girls like you, my dear followers. Well, let him not move, at least breathe.

Therefore, we can determine the smallest increase in freedom by measuring our chest girth by taking a deep breath. I checked, cm 2 is added to the chest girth.

Therefore, we can determine the smallest increase in freedom by measuring our chest girth by taking a deep breath. I checked, cm 2 is added to the chest girth.

Here, we have identified. The smallest increase in chest girth is 2 cm. With such an increase, you will get the same shirt as the girls from the post "Always fashionable shirt"

But, if you plan not only to breathe in this shirt, but also to move, then the allowance for freedom of fitting to the chest girth should be increased to 6-8 cm. We get a semi-adjacent silhouette.

For a completely loose shirt, we give an increase of 8 cm.

Now to the hips.

The increase in freedom of fitting to the girth of the hips (we move this place not so intensively) is customary to take 0.5 of the increase in the chest. But at least 2 cm.

I do not give an increase to the waist, since during the construction we make the waist darts to the minimum, and remove the excess during fitting.

An increase in the width of the back (Шс) and in the width of the chest (Шг) is also important.

To the width of the back, you need to add from 4 cm, to the width of the chest - 80% of the increase in the width of the back.

When you start drawing a drawing, you will understand how much to add to the width of the back and chest. It should correspond to the length of the shoulder and the total width of the product in the chest area.

We make additions to the lengths only if you are sewing a very loose shirt. Then add 0.5 cm each to Dpt (Length of the front to the waist) and Dst (Length of the back to the waist).

We will increase the width and depth of the neck after construction.

Creating a shirt pattern

1. Draw a horizontal line. This is the waist line. We sign so as not to get confused.

2. Departing 5 cm from the right edge of the paper, put a point on the waist line through which we draw a perpendicular. This is the mid-front line.

3. Set aside from the waist up along this midline in front of the Dtp measurement (Front waist length). Let's call the resulting point O.

4. To point O we draw a perpendicular to the left.

5. Along this perpendicular, we postpone the value of Osh (Neck circumference): 6. Let's call the resulting point Ш.

6. Downward from point O we set aside the depth of the neck. It is 1 cm larger than the width.

7. Set aside further to the left of point W the measurement Dp (shoulder length). We call point P.

8. From point P, lay down 4 cm for the shoulder bevel. Let's call the point P1.

9. We draw line ШП1. Extend slightly beyond point P1.

10. From the waist down along the line of the middle of the front, set aside the value of About (hip girth): 5.

Draw a perpendicular from the resulting point to the left. This is the hip line. We sign.

That is, the distance from the waist line to the hip line is calculated using the formula About: 5.

1. From the middle of the front along the line of the thighs, set aside the value of About (girth of the hips) plus an increase in the hips: 2.

From the resulting point, draw a perpendicular upward. This is the line in the middle of the back.

2. Along the line of the middle of the back up from the waist, lay down the Dst measurement (Length of the back to the waist). We call the resulting point O1.

3. Draw a perpendicular from point O1 to the right. We put off the value of Osh (Neck circumference) on it: 6. Set point Ш1.

4. Set aside 2 cm down from point O1. This is the depth of the neck.

5. From point Ш1 to the right, set aside the measurement Dp (shoulder length) plus 1 cm for landing. Let's call point P2.

6. From point P2 down, set aside 3 cm for the shoulder bevel. We get point P3.

7. Draw line Ш1 П3. Set aside the Dp + 1 measurement on it again.

8. We check whether the measurement in the drawing corresponds to Vpk (oblique shoulder height). If more, leave until fitting. The main thing is not less. If less, then reduce the shoulder bevel (distance P2 P3).

9. From the waistline, lay up the Wb measurement (side height). We draw a line from the middle of the back to the middle of the front. Let's sign "chest line".

We calculate the width of the shelf and back along the chest line.

Og2 (chest girth 2) plus the increase in the chest divided by 4. Now add 2 cm to the shelf, and subtract 2 cm from the back.

For example, Og2 is 100 cm.Plus an increase in the chest of 8 cm.

It turns out (100 + 8): 4 = 27. The shelf width will be 27 + 2 = 29. Back width 27-2 = 25.

We postpone the resulting values along the chest line.

The resulting point of the shelf width will be called Bp, the backs - Bs. They will still be useful to us.

On the waistline, we make the shelf and back 1-1.5 cm narrower than these details at chest level.

We postpone the resulting values along the waist line.

We calculate the width of the shelf and back along the hip line.

It is calculated in the same way as for the chest.

About (hip girth) plus the increase in the hips divided by 4. Add 2 cm to the shelf, subtract 2 cm from the back.

We put aside the resulting values along the line of the hips.

We draw a side line, connecting the corresponding points on the line of the chest, waist and hips.

Let's finish the shelf.

1. From the line of the middle of the shelf, draw a parallel line at a distance of Cg (Center of the chest): 2.

Let this line start from the hip line and end at the shoulder line.

At the intersection of this line with the shoulder line, let's put the point G1.

2. From point Г1 downward on the resulting line, set aside the measurement Вг (chest height). Let's call point G.

3. From the point G1, we postpone to the left along the shoulder line the value (Og2 - Og1) +5. Let's call the point Г2. We connect points G2 and G. It turned out a bust dart.

4. We fold the paper, closing the dart. With the dart closed, we continue the shoulder line from point Ш through point Г1.

5. Set aside on the new shoulder line the measurement Dp (Shoulder length).

6. With the dart closed, set aside the Wr measurement (chest width) plus an increase. We draw a line for laying this measurement in the middle between the depth of the neck and the line of the side height.

7. Draw a smooth line from the point of the end of the shoulder, through the width of the front to the point Bp. This is the armhole line. We will sew in the sleeve here.

8. Check that the armhole line is at right angles to the shoulder line. If not, correct without reducing the length of the shoulder.

9. From point D down, set aside 2 cm. This is the beginning of the waist dart of the shelf. The end of this dart will be at the hip line. Set aside at the waist 1cm each side of this dart. Draw a dart.

Let's finish the back.

1. Set aside in the middle between the depth of the neckline and the line of the side's height the measurement Шс (Backrest Width) plus an increase.

2. Draw a smooth line through points P3, the width of the back to point Bs.

3. Parallel to the line of the middle of the back, at a distance equal to Cg (Center of the chest): 2 −1. draw a line. This is the line of the waist dart on the back. It goes from the hip line to the side height line.

4. On the waistline from this line, set aside 1 cm in both directions. Before trying on, it is enough. We connect all sides of the dart.

The drawing is almost complete. It remains to make small adjustments specifically for the shirt.

1. We deepen and widen the neckline by 1 cm on the shelf and on the back. This is not to suffocate with the collar.

2. Draw another line parallel to the middle line of the shelf at a distance of 6 cm. Our shirt will be fastened with a strap.

Look like that's it.

Now the important thing! We measure and check the drawing for compliance with the measurements.

Transferring the dart

For a checked shirt, we cannot leave the chest dart on the shelf where it is - in the shoulder seam. Move the dart to the side seam. There, the displacement of the cell will be less noticeable.

This is done simply: draw a line from side seam(we start 5-7 cm below the armhole) to the point where the tuck starts. We cut the pattern along this line, open a new dart, while closing the old one. The only thing, make a new dart 2 cm shorter.

Here is a picture of my cut. The new dart start point is marked with a pink dash.

If you want, you can carve out yokes on the shelves and / or back. Just draw the desired yoke line on the pattern and cut.

Everything else is in order, you can start cutting.

It is more convenient, of course, to use full pattern shirts, not half. If you are not lazy, then finish the second half of the back.

When cutting plaid fabric we will take into account the following rules:

The most noticeable stripes are placed in the middle of the main parts, sleeves, yokes and collars.

The dominant transverse stripes are placed at the bottom or along the sleeve.

Do not put bright stripes at chest, waist or hips - they widen the silhouette.

The transverse stripes must match at the seams. It is easier to combine the cells if, when cutting, lay out adjacent parts side by side. You can navigate along the bottom, you can use the waist line.

Luxurious when the cells on the shoulder seams match.

The pattern on the pockets and flaps should match the pattern of the parts on which they are located. If you don't want to suffer, cut out small parts and yokes at an angle of 45 degrees. By the way, this will decorate the shirt.

If you do cut the fabric in half, often and often pin it together to avoid misalignment.

Important!

Having pricked the part on the fabric, once again check the coincidence of the cells, the direction of the share, the seam allowances.

Construction of a sleeve pattern

Now about the sleeve.

1. Draw two perpendicular lines. The intersection point is called O

2. We calculate the height of the okat. Measure the length of the armholes on the front and back, fold and divide by 3. For a shirt, subtract 1. For a short wide sleeves- 2 cm.

3. Set aside the resulting value upward from point O. We get point O1

4. We calculate the width of the sleeve: shoulder girth (Op) plus an increase in the freedom of fitting. For a shirt, this is 6-8 cm.

5. Set aside the resulting value equally in both directions from point O. We call the resulting points P and C

6. We connect P with O1, C with O1.

7. Divide PO1 in half, and the resulting segments in half.

8. Divide СО1 in half, the resulting segments are still halved.

9. Draw a curve from point P to point O1 with a deflection of 1.5-2 cm in the first half, and 1.5 cm in the second.

10. Draw a curve from point C to point O1 with a deflection of 1 cm in the first half, and 1.5 cm in the second.

Take a look at the drawing. All these deflections and "bends" I designated in the drawing with the corresponding numbers.

11. Set aside the length of the sleeve from the point O1 down. Let's call the point Н

12. On both sides of the H, we equally distribute the width of the sleeve at the bottom in half.

13. Connect the resulting points with P and C, respectively.

14. We measure the size of the ridge of the front part of the sleeve. This is the PO1 curve. Compare with the size of the shelf armhole.

15. Measure the size of the back of the sleeve. This is the CO1 curve. Compare with the size of the back armhole.

If the ridge of the sleeve of the back corresponds to the armhole of the back, and the front of the ridge of the sleeve corresponds to the armhole of the shelf, then that's it, the sleeve is ready.

Most often, the armhole of the shelf is smaller than the armhole of the back. Consequently, the ridge of the sleeve of the front part should also be smaller. We measure how many centimeters the difference is and from the front of the sleeve we cut off half of this difference, and add to the back of the sleeve. Look at the drawing. The new outline is turquoise.

When I build on paper, I directly take and cut a strip from the front of the sleeve, glue it to the back.

We cut out, sweep the details

Fitting a shirt

Where to start sewing a shirt after trying on

After trying on, we make changes to the cut. First, in a pattern, it will most likely come in handy for you, and then in a cut.

We start sewing:

1. If there are yokes, we grind them to the main details

2. Sewing darts (chest and waist)

3. We carry out processing of the middle cut of the shelf with a bar

4. Sew the shoulder seams, combining the pattern, process the cut

I'll tell you a little more about the bar.

Remember when we added 6 cm to the middle of the shelf?

The simplest thing is to tuck the middle cut on the wrong side by 1 cm and tuck it again by 3.5 cm. Sweep, stitch over the face. That's the whole bar. You can also stitch it along the edge.

Further:

You can already decide on the size of pockets, valves, cut them out.

The top of the pocket is processed with an overlog or hemmed seam with a closed cut. The side and bottom edges of the pockets are tucked in and tucked in.

We glue the upper pocket flap with non-woven material.

We fold the upper and lower valves face to face, chop off or sweep, as we are used to, grind. We cut the seam allowances step by step, cut the corners.

Try on a shirt and determine the location of the pockets and flaps. Baste and stitch them.

How to sew a collar with a stand

We apply the pattern of the collar and the stand on the fabric folded in half, observing the direction of the share thread and, accordingly, the pattern of the fabric, we circle it once along the contour, the second - with allowances for the seams. We cut out. We check that there are 2 parts of the collar and 2 parts of the stand.

The upper collar and the upper part of the stand are duplicated with non-woven fabric.

First, fold the collar details face to face

chop off

Stitching the collar details, stitching on the smaller bottom detail

we make stepped trims to reduce the thickness of the seam allowances

we cut the allowances at the corners

turn out

we sweep

fold the collar in half - check the "sameness" of the left and right corners

we spend in the edge or on the foot

ironing

Here is a photo where the roll of the front part to the wrong side is clearly visible.

Next stage:

We pin the stand to the collar, grind it.

Please note: we apply the inner side of the stand to the front side of the collar, and the outer side to the wrong side. For precision, start chipping from the middle.

Step by step cut allowances for the seams of the rack

We turn it out

we sweep

check for the "sameness" of the left and right sides

Here's my collar. I made the bottom of the collar and stand from a different fabric.

We attach the collar stand with the outside to the front of the shirt, pin it with pins, grind it.

Inner side we pin the racks to the seamy side of the shirt, carefully mark, grind.

Consider a ready-made men's shirt. See how neatly the post is sewn to the neck?

Do you think it's all about the professionalism of the seamstresses? Not only. There is little secret... Now I’ll tell you about it.

Before stitching the stand to the collar, a fold is made on the inner part of the stand to the width of the allowance. The allowance is wrapped, with which the stand is stitched to the neck. It needs to be swept or stitched on the wrong side. We begin to process the rack with the fold already made.

This will allow you to neatly and easily stitch the stand to the neck in the future.

Finishing the shirt sewing

If you have sleeves, then:

Pin and stitch the sleeves, aligning the half-piping of the sleeve with the shoulder seam.

Stitch the side seam and the sleeve seam with one stitch.

I have a sleeveless shirt and the armholes will be welted.

If you also sew a shirt without a sleeve, then:

Cut out a roll (bias tape) 4 cm wide. Fold it in half, sew it like this to secure it.

Pin, stitch the roll to the armhole across the face

Turn inside out, baste, stitch neatly along the edge of the steering wheel

Iron

Are your pockets ready?

No? Let's get ready.

Fold over the top of the pocket, turn it inside out, sew. Tuck the rest of the pocket inside out and welt. Pin the finished pockets in place, sweep, grind.

Fold the cut-out flaps face to face. Chip, making a slight overlap of the upper part of the valve to the lower, so that later you get a pretty roll, grind.

Cut the seam allowances stepwise, trim the corners.

This stylish fitted shirt can be a staple of any wardrobe. The shirt is ideally combined with trousers, shorts, plain and bright voluminous skirts. You must sew it, and then you will always have something to wear!

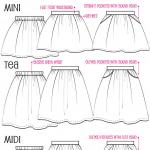

Blouse modeling is performed by. The sleeve is modeled according to the basic pattern of a one-seam sleeve. You will also need a stand-up collar.

ADVICE! You can sew this shirt not only from denim, but also from any other shirt fabric.

Rice. 1. Modeling the back of a fitted shirt

Modeling the back of a shirt

Draw a back yoke 13 cm wide. From the tops of the tucked dart, extend the vertical section up to the yoke. From the line of the hips on the side, set aside 4 cm upward. Draw the line of the bottom of the back along the line of the hips, then lift up to the side to point 4, bending smoothly. Cut along the yoke line and along the dart lines to the yoke along the red dotted line. Cut out the dart.

Modeling a shirt shelf

Rice. 2. Modeling a shirt shelf

Transfer the bottom line of the shelf from the back pattern. Cut along the bust line and along the tuck line. Close the bust dart. Draw a yoke for the shelf. Draw a 3 cm wide cut-off bar for a shirt along the middle of the front (1.5 cm in each direction). Cut the strap and yoke.

Sleeve pattern

Rice. 3. Modeling sleeves and cuffs

When modeling sleeves, use a straight sleeve pattern. The width of the sleeve at the bottom is equal to the circumference of the wrist by the measure + 7 cm. Divide the width of the sleeve at the bottom into 4 parts and from the left dividing point draw up a vertical dotted line along the line of the ridge of the sleeve.

Calculate the excess width for the tapering of the sleeves (Width of the basic pattern minus the Girth of the wrist with an increase) and divide it into 3 sections. Tuck the sleeve to the left, right, and right of the cut line. From the resulting point, connect with a dotted line with an okat. Shorten the sleeve 5 cm. Cut the sleeve into 2 pieces. In addition, draw a rectangular cuff 10 cm wide (finished 5 cm) and equal to the wrist circumference + 6 cm.

Collar pattern

Rice. 4. Details of the cut of the fitted shirt

Cut out from the main fabric:

- The middle part of the back - 1 piece with a fold

- Back side part - 2 pieces

- Shelf - 2 parts

- Back yoke - 1 piece with a fold

- Shelf coquette - 2 parts

- Plank - 2 parts

- Upper part of the sleeve - 2 pieces

- Elbow sleeve - 2 pieces

- Collar stand - 2 pieces with a fold

- Collar fly-off - 2 pieces with a fold

- Pocket - 2 pieces

- Pocket flap - 4 pieces

Additionally cut out: strips for processing the sleeve cut - 2 parts and edging for processing the sleeve cut - 2 parts 3 cm wide and 13 cm long.

See more: How to cut a placket for processing a sleeve cut

Allowances on all sides - 1.5 cm.

Fold the allowances at the bottom of the shirt by 0.7 mm and stitch along the edge. On the placket and cuffs, set the buttons according to the markings or sweep the loops and sew on the buttons.

Your shirt is ready! Wear it with pleasure and be happy!

The white shirt is refreshing and elegant. It never goes out of style. Along with the little black dress, the classic women's shirt has the status of a cult item.

Ideally, it repeats a men's shirt and looks a little larger in size, which makes its owner fragile. A women's shirt, as a rule, is sewn without darts, but options are possible: it can be more tight-fitting, with darts or reliefs, made of cambric, good quality cotton or silk. If you sew a women's shirt with your own hands from a checkered fabric, you get a cowboy shirt, from a fabric with a large floral pattern - a Hawaiian one.

What are the main details of a shirt?

This is a turn-down collar on a stand, a placket, a lowered armhole, sewing seams, a double yoke and sleeves with cuffs and slits, like in a men's shirt. But in a women's shirt, the straps may be narrower or wider than the standard ones (for a men's shirt, this is 3 cm), the collars and cuffs are not so rigid, the buttons may already have two holes (it is believed that in men's shirts buttons with only four sewing holes are used). Also, in women's shirts, instead of sewing shirts, there can be ordinary seams processed with an overlock and without stitching.Pattern:

Blouse shirt. You will need: Blouse A. Cotton 1.80-1.80-1.85-1.85-2.10-2.10-2.10 m with a width of ...

Pattern:

A crinkled cambric shirt goes well with shorts. Size 34-42 You will need: Baptiste ...

Burda catalog autumn-winter / 2015/2016

Pattern:

Slim fit denim shirt classic style... You will need: Shirt A, B and C. Cotton rub ...

: Master Class

In order not to repeat ourselves and teach you something new, in the master class "How to sew a women's shirt", the processing of some knots has been changed.As a basis, on which we sew a women's shirt with our own hands, we take a pattern of model 120 from:

Pattern:

Loose blouse-shirt with low armholes, as if borrowed from a men's wardrobe, pr ...

With my size 38, I took a pattern one size smaller - 36 solution. The shirt model turned out to be quite voluminous, especially in the shoulder girdle. It doesn't matter which pattern to take, all shirts are sewn in general the same way.

You will need:

Shirt fabric - 1.5 m with a width of 140 cm;Non-woven fabric - 30 cm;

Buttons - 10 pcs.;

Tailor's scissors ();

Bias binding for finishing;

Threads and sewing needles;

Tailor's pins ();

Tracing paper ();

Pencil or felt-tip pen for marking ();

Ruler ()

Step 1. Preparing a pattern for a women's shirt

I had to shorten the length of the pattern.Since the bottom of the shirt is curly, I laid a transverse fold on the pattern above the bottom line so as not to change it.

The sleeve is shortened in the middle of the sleeve, again in order not to change the bottom line with markings, because the bottom of the sleeve is designed for the length of the cuff.

Often a stitching bar is given in the magazine. Whenever possible, I replace it with a one-piece one, this greatly simplifies its processing.

To do this, the paper part of the strip must be glued to the part of the shelf and one more width should be added to obtain a double strip (a strip with two folds). The second flap of the plank replaces the glue pad, which, again, simplifies the work.

Step 2. Cut

We cut out the details of the shirt with the same allowances along all the cuts of 1.5 cm.

Important! The planks are cut out without allowances.

There are many small parts in the shirt that strengthen the glue, so it is better to first mark the location of these parts on the fabric (uprights, collars and cuffs), then cut this piece of fabric and strengthen it with glue. And only then cut out all the small details from the glued fabric. This speeds up the work, and the cut is more accurate.In a women's shirt, you need to strengthen all paired parts of the stand, collar and cuffs with a thin glue with a thin glue.

For these purposes, glue G785 is perfect, as well as non-woven H180 and their analogues. Duplicate material should be thin and pliable, unlike a man's shirt.Then, using the glue, we mark all the allowances on small parts.

, read the website

Step 3. Processing planks

The planks are processed first of all after cutting, even before the first fitting, because they do not affect the fit of the product in any way.To do this, you need to chop off or bend the paper strip on the pattern and, with an iron, without chipping off the pattern, press the strip twice on the wrong side of the shelf, first on one part, then turn over the shelves and iron the strip on the other part. Chop the planks on the shelf.

Then stitch the strips onto a shelf 1 mm from the fold (to the edge) and mark the loops and buttons on them with an aquamarker. This is for fitting. The hinges run along the plank and in the middle of it.

Do not forget that on the patterns in the magazine, the markings for the loops are given for the smallest size! Consider this when making a pattern.

Step 4

Fold over the back and sew along the seam allowance. This will fix her. Sweep the shirt for the first try-on. It is enough for her to sweep only one piece of the yoke. The second yoke is sewn after fitting. Try on your shirt, fit it to your figure.

Step 5. Processing of yokes

In order to sew on the second yoke, you will have to dissolve the basting on the sides after trying on.Lay the shirt face up on the table.

Roll the backrest piece onto the yoke with a tube.

Roll up the details of the shelves on the yoke.

Put the second yoke on top, face down and chop off with the lower yoke. The twisted details of the shelves and back remain inside, between the yokes.

Sew the details of the yokes. Trim allowances to 5-7 mm.

Unscrew the yokes, pull the parts of the shelves and backs out through the neck.

Press on the seams of the yoke. Topstitch them from the front of the shirt, if necessary according to the model.

Step 6. Processing the collar

Fold the collar details face to face, chop them off and stitch along the markings. Cut allowances in corners up to 1 mm from the line and trim to 5 mm.

Press the collar allowances on the last.

Turn collar out, press iron on without piping and topstitch around edge.

Trim the bottom allowance on one part of the rack.

Trim the trimmed bottom cut. To do this, apply an oblique inlay made of finishing fabric (for me it is tie silk) and stitch it onto the lower cut of the rack 5-6 mm from the edge.

Wrap the edge of the rack with tape and iron it.

Place the stitch exactly in the seam where the inlay is sewn (just below the bias inlay), grabbing the second cut of the inlay from the inside out.

Pin a stand without inlays with your face on the lower collar. Align the cuts, the middle, check the symmetry of the ends of the stand, folding the collar in half with the pinned stand.

From the side of the upper collar, lay the edged stand face down.

Stitch the racks, grabbing the collar between them. Trim allowances in roundings to 1 mm, in other areas to 7 mm.

Unscrew the uprights, press them down without the transition edge.

Important! We iron either the collar or the stand separately so that the collar does not lose its shape.

Draw the collar stitching line along the top stand.

Step 7. Sewing in the collar

Mark the middle of the stand and the middle of the collar. Stick the collar into the neckline from the front of the shirt, combining the midpoints, ends of the collar and the straps, as well as marks on the shoulder seams. Sew the collar into the neckline, stitching exactly along the marked line.

Cut out seam allowances at the ends of the collar, press the stand allowances.

Pierce the second strut over the seam so that it overlaps the stitching.

Basting the stand so that the basting goes on one side along the edge of the bias tape, and on the other side in the seam of the collar stitching. It is better to leave pins in the corners of the collar for better fixation of the stand.

Stitch exactly to the edge of the binding. Iron the rack finally.

Step 8. Processing the curly bottom of the shirt

You can work the bottom of the shirt in the classic way by tucking the seams in twice and stitching them. But my bottom of the shelves is much shorter than the bottom of the back, so it's better to process it separately at the shelves and back.Fold two shelves, check the symmetry of the bottom, trim it in case of unevenness.

Fold the shelves with the back. Where the bottom rounding ends, make notches of 5-7 mm along the allowances. This will be the end of the side seam.

Trim the bottom of the shelves and backrest separately with an oblique inlay (just like the stand, you just need to tuck the second cut of the inlay). Bend the ends of the tape inward at the strips.

Step 9. Sleeve slits

Cut the bottom of the sleeve along the markings.

Trim the side of the cut that is closer to the sleeve seam with a bias tape.

Make a cut strip pattern. The cut width of the plank is 4 cm (finished 2 cm).

The length of the strap is 3 cm longer than the length of the cut. The top of the plank can be made as a corner or straight.

Cut out planks with 1 cm allowances.

Fold the planks in half lengthwise, grind the upper corner along the markings (3 cm above the cut).

Cut and trim allowances in the corners to 5 mm. At the end of the seam, make a notch along the seam allowance.

Unscrew the planks, press them down. Along the fold of the plank to the height of the cut, lay a finishing line.

From the front of the sleeve, place and stitch a placket on the second side of the cut. Notch the seam allowance above the seam.

Press the allowance to the inside of the plank, pin the second fold of the plank over the stitching seam.

Pin the bar over the cut and stitch on the cut along the edge and top corner.

Here's what happened.

Step 10. Sewing in the sleeve

On the front side cover the sleeves with 5-6 mm width allowances and iron them.

Stick the sleeve into the armhole so that the armhole allowance does not protrude beyond the fold of the armhole allowance.

Sew the sleeve into the armhole 6-7 mm from the fold of the sleeve allowance. Important! The seam must be at the same distance from the fold of the allowance, otherwise the seam will not be straight.

Press the seam allowances onto the armhole, pin and baste.

Stitch the armhole allowance exactly along the hem of the allowance.

View of the sewn-in sleeve from the face of the shirt.

Step 11. Side seams

Fold the allowances of the side seam and the seam of the sleeve so that one allowance protrudes 6-7 mm behind the other, chop them off and grind them 6-7 mm from the smaller cut.

You can fold the seams straight, but then you have to trim one seam allowance. The first way is easier and faster.

Iron the protruding allowance to a smaller one.

Then lay out the details of the shelf and back, iron the allowances, then pin on the seam and stitch on the details of the sleeves and shelves.

On the front side, a seam with stitching turned out. Double-stitching seam inside out.

Step 12. Treatment of the cuff

On the outer cuff, press the hem allowance to the wrong side and topstitch it 1 cm from the fold.

Fold the cuff pieces face to face and sew along the markings. Trim the allowances in roundings to 1 mm, the rest - up to 5-6 mm from the line.

Iron the allowances on the last, like at the collar. Unscrew the cuff and press it on without the transition piping. Draw the cuff stitching line along the fold line of the outer part.

Topstitch the outside edge of the cuff, starting and ending at the bottom cross stitch!

Place pleats at the bottom of the sleeve. From the front side, the folds of the folds look at the sleeve slit.

Insert the cuff into the sleeve from the wrong side! Sew on cuff along the markings. Trim seam allowances to a corner at the ends of the cuff.

Press cuff allowances. Pin the rolled-up edge of the cuff from the front of the sleeve, overlapping the stitching line.

Stitch the cuff along the hem of the fold. It turns out that on the front side, the cuff has two parallel finishing lines on the bottom.

Step 13. Loops

Punch the loops along the markings, sew on the buttons. The loops on the bar run in the middle and along the bar, on the stand - along the stand, on the cuff - along the cuff and 5-7 mm from its short edge. The length of the buttonhole is equal to the diameter of the button plus 2 mm.

The buttons are sewn on a thread leg.

Svetlana Khatskevich

Svetlana graduated from a university with a degree in sewing production engineer. He has been teaching sewing technology for over 20 years. He is a senior lecturer at the AcademyBurda ". We know Svetlana from her work on the site since its inception. She generously shares her knowledge and infects her with her love of sewing.Sewing is creativity, fun and educational. Welcome to this bright and interesting world!

Hello.

In this article, we will learn how to build a shirt structure.

Shirt-cut clothes are primarily distinguished by the parameters and configuration of the armholes. The size of the shirt armhole is larger than the size of the armhole of the basic design of the dress, and the configuration of the shirt armhole is wider and deeper. Therefore, the details of the shirt pattern - the back and the shelf also differ in their parameters and configuration.

There are two ways to construct a shirt design: apply constructive modeling of the basic dress pattern, or use the developed methodology for constructing a shirt design. In this article, we will look at the second option.

To build a shirt pattern, we need the following measurements:

Name of measurements and symbols | cm |

|---|---|

Semi-girth of the neck (US) | |

Semi-girth of the chest (Cg) | 40,5 |

Waist girth (St) | |

Half hip (Sat) | 44,8 |

Back length to waist (dts) | |

Breast height (Bg) | |

Shoulder length (dp) | |

Product length (Di) |

In this cutting technique, we will consider two shirt silhouettes: semi-adjacent and straight... A shirt of a semi-adjacent silhouette assumes the presence of chest and waist darts, while the product is quite free and dynamic. The shirt of a straight silhouette has no darts, and the product itself is more free. As a result, the cut of these two silhouettes differs not only in the additions to a free fit, but also in some construction constructions. To construct a pattern for a shirt in a straight and semi-adjacent silhouette, we will use the following allowances for free fit:

The increase along the chest line between the details of the structure is distributed as follows:

We will prepare a blank sheet of paper, the length of which is 5-10 cm longer than the measurement of the length of the product.

Drawing grid

Product length and width... Having departed 5 cm from the top edge of a sheet of paper, draw a rectangle AA 1 H 1 H, where the sides AH and A 1 H 1 are equal to the measurement of the length of the product, and the sides AA 1 and HH 1 are equal to the measurement of the half-girth of the chest with an increase in free fitting (AH = A 1 H 1 = Di = 68cm; AA 1 = HH 1 = Cr + CO = 40.5 + 5.5 = 46cm). note, in this example, I used an increase for a semi-adjacent silhouette, if you draw a straight silhouette, then do not forget to substitute the corresponding increases for free fitting in the formulas (see the table above).

Armhole depth... From point A downward in a straight line, set aside 1/3 measurements of the half-girth of the chest + CO (see the table of increments) and put the point G (segment AG = 1 / 3Cg + CO = 40.5: 3 + 9 = 22.5 cm). From point Г to the right we draw a horizontal line to the intersection with the segment А 1 Н 1, the point of intersection is designated Г 1.

Back width... From point G we set aside 1/3 measurements of the half-girth of the chest + CO (see the table of the distribution of the increase along the chest line) and get the point G 2 (segment GG 2 = 1 / 3Cg + CO = 40.5: 3 + 3cm = 16.5cm) ... From the point Г 2 upwards, construct a perpendicular to the intersection with the side AA 1, the point of intersection is designated P.

Armhole width... From G 2 to the right, set aside 1/4 measurements of the half-girth of the chest + CO (see the table of distribution of the increase along the chest line) and mark the point G 3 (G 2 G 3 = 1 / 4Cg + CO = 40.5 / 4 + 0.5 = 10.6cm). From the point Г 3 upwards we draw a perpendicular to the intersection with the side AA 1, and the point of intersection we denote by П 1.

Waistline... From point A downwards, we postpone the measurement of the length of the back to the waist and put the point T (AT = Dts = 40cm). From point T we draw a horizontal line to the intersection with side A 1 H 1 and designate the point of intersection T 1.

Thigh line... From point T downwards, set aside half the measurement of the length of the back to the waist and put point B (TB = 1 / 2Dts = 40: 2 = 20cm). Draw a horizontal line from point B to the intersection with the segment A 1 H 1, mark the intersection point B 1.

Side line... Divide the segment Г 2 Г 3 in half, the intersection point is designated Г 4 (Г 2 Г 4 = Г 4 Г 3), and down from this point we lower the perpendicular to the intersection with the bottom lines, the intersection point is designated Н 2, and the points of intersection with the waist lines and hips - T 2 and B 2.

Auxiliary points of the armhole... We divide the segments G 2 P and G 3 P 1 into three equal parts, the lower points of division will be designated P 2 and P 3 (see Fig.).

Back construction

Back neck cut... From point A to the right, set aside 1/3 measurements of the half-girth of the neck + 0.5 cm (for all silhouettes) and get point A2 (AA 2 = 1 / 3Cw + CO = 15: 3 + 0.5 = 5.5cm). Up from point A 2, set aside 3cm (for all silhouettes) and mark point A 3 (A 2 A 3 = 3cm). We will draw the line of the neck with a smooth line, observing the right angle at point A.

Shoulder section of the back... From point P downwards, we put off 3cm (for all silhouettes) and put point P 4 (PP 4 = 3cm). Now we connect points A 3 and P4, and on the resulting straight line from point A 3 we postpone the measure of the length of the arm + CO (see the table of increments) and put the point P 5 (A 3 P 5 = Dp + CO = 13 + 1.5 = 14 , 5cm).

Back armhole cut... We connect the points P 2 and G 4 with a dotted line and divide this segment in half, and from the point of dividing down we set aside 2 cm at a right angle and put the point P 6.

Let's make a cut of the armhole with a smooth concave line, connecting the points P 5, P 2, P 6 and G 4.

Back yoke... Set aside 8cm down from point A and put point K (AK = 8cm). From point K to the right, draw a horizontal line to the intersection with the line of the armhole of the back, and the point of intersection is designated K 1.

Down from the point K 1 along the armhole line, set aside 1 cm and put the point K 2 (K 1 K 2 = 1 cm). Connect point K 2 with a smooth line with the yoke line.

Building a shirt shelf in a straight silhouette

Cut of the neck of the shelf... From point G 1 upwards, set aside half the measurement of the half-girth of the chest and put a point P (G 1 P = 1 / 2Cg = 40.5: 2 = 20.3 cm). Draw a horizontal line of arbitrary length from point P to the left.

Now, from point P to the left and down, we postpone 1/3 measurements of the half-girth of the neck + 0.5 cm and mark points P 1 and P 2 (PP 1 = PP 2 = 1 / 3Cw + CO = 15: 5 + 0.5 = 5.5cm ). We connect points P 1 and P 2 with a dotted line, which we divide in half and from point P through this division point we postpone 1/3 measurements of the half-girth of the neck + 0.5 cm and get point P 3 (PP 3 = 1 / 3Cw + CO = 15: 5 + 0.5 = 5.5cm).

Let us draw a smooth line to cut the neck through points P 1, P 3 and P 2, observing a right angle at point P 2.

Shoulder cut of the shelf... Let's build an auxiliary line, connecting point P 1 with the upper division point of the segment PG 2 (see Fig.), On this line from point P 1 to the left, set the measure of the arm length + CO and put the point P 7 (P 1 P 7 = DP + CO = 13 + 2 = 15cm). Pay attention, now we are considering the construction of a straight silhouette shirt shelf, so the increase in the formula corresponds to the increase for a straight silhouette.

Shelf armhole cut... We connect the points P 3 and G 4 with a dotted line, divide this segment in half, from the point of division we lower the perpendicular 2 cm in size and mark the point P 8.

Let us draw a smooth line for the cut of the armhole, connecting the points P 7, P 3, P 8 and G 4.

This completes the construction of the shirt with a straight silhouette.

Our pattern is ready!

Constructing a shirt shelf in a semi-adjacent silhouette

Cut of the neck of the shelf... From point G 1 upwards, set aside half the measurement of the half-girth of the chest + 0.5 cm and put the point P (G 1 P = 1 / 2Cg + CO = 40.5: 2 + 0.5 = 20.8 cm). Draw a horizontal line of arbitrary length from point P to the left.

Down and to the left of point P, set aside 1/3 measurements of the half-girth of the neck + 0.5 cm and mark points P 1 and P 2 (PP 1 = PP 2 = 1 / 3Cw + CO = 15: 5 + 0.5 = 5.5cm) ... We connect points P 1 and P 2 with a dotted line, which we divide in half and from point P through this division point we postpone 1/3 measurements of the half-girth of the neck + 0.5 cm and get point P 3 (PP 3 = 13 / Cw + CO = 15: 5 + 0.5 = 5.5cm). Let us draw a smooth line to cut the neck through points P 1, P 3 and P 2, observing a right angle at point P 2.

Shoulder cut and bust dart... To the left of point P 1, set aside 4 cm and put point B (P 1 B = 4 cm), down from point B, set aside 1 cm, we get point B 1 (BB 1 = 1 cm). Let's connect points P 1 and B 1.

Add the lengths of the segments PP 1 and P 1 B (5.5 + 4 = 9.5 cm), subtract 1 cm from this sum (9.5-1 = 8.5 cm), postpone the resulting value to the left of the point G 1 and put the point G 5 (G 1 G 5 = PP 1 + P 1 B-1 = 8.5 cm). We connect points G 5 and B 1, the segment G 5 B 1 - the right side of the chest dart.

Now we will construct an auxiliary line by connecting point B with the upper division point of the segment PG 2. Upward from point Г 4, draw a vertical line to the intersection with the auxiliary line, the intersection point is designated by O.

To the right of point O, we postpone the shoulder length on the auxiliary line with an increase in free fitting minus the length of the segment P 1 B and put point B 2 (ОВ 2 = Дп + СО-Р 1 В = 13 + 1.5-4 = 10.5 cm) ... Further, from point Г 5 upwards through point В 2 we draw a segment, the length of which is equal to the right side of the dart and get point В 3 (Г 5 В 3 = Г 5 В 1).

Down from the point O, set aside 3cm and put the point O 1 (OO 1 = 3cm). Connect the points O 1 and B 3 with a thin line.

From point B 3 to the left along a thin line, we postpone the length of the shoulder with an increase in free fitting minus the length of the segment P 1 B and put the point P 7 (B 3 P 7 = Dp + CO-P 1 B = 13 + 1.5-4 = 10 , 5cm).

Shelf armhole cut... We connect the points P 3 and G 4 with a dotted line, divide this segment in half, from the point of division we lower the perpendicular 2 cm in size and mark the point P 8. Let us draw a smooth line for the cut of the armhole, connecting the points P 7, P 3, P 8 and G 4.

Calculation of the solution of darts along the waist line... From the width of the product, we subtract the measurement of the waist half-girth with an increase in free fitting (AA 1 - (St + CO) = 46- (30 + 3) = 13cm), the result obtained is the sum of the solution of all darts along the waist line, where

the size of the solution of the front dart = 0.25 of the total solution of the darts (13 x 0.25 = 3.3 cm),

the size of the lateral tuck solution = 0.45 of the total solution (13 x 0.45 = 5.8 cm),

the size of the solution of the back tuck = 0.3 of the total solution (13 x 0.3 = 3.9 cm).

Determination of the width of the shirt along the hips... Now, from the measurement of the half-girth of the hips with an increase in free fitting, we subtract the width of our product (Sb + SO-AA 1 = 44.8 + 4-46 = 2.8 cm), the result obtained is the value of the expansion of the product along the line of the hips.

Side cut... From point T 2 along the waistline to the right and left, set aside half of the solution of the lateral tuck (we calculated its value a little higher) and mark the points that we connect with straight lines to point G 4.

From point B 2 along the line of the hips to the right and to the left, set aside half the size of the expansion of the product along the line of the hips and put points that we connect with smooth convex lines with the points of the solution of the lateral dart at the waist and extend these lines to the intersection with the bottom line.

Construction of a tackle dart on the back... To the right of point T, we postpone 1/3 measurements of the half-girth of the neck + 0.5 cm and put the point T 3 (TT 3 = 1 / 3Cw + CO = 15: 3 + 0.5 = 5.5). From point T 3 to the right, we postpone the value of the entire solution of the tuck of the back and get point T 4 (T 3 T 4 = 3.9 cm).

Divide the T 3 T 4 segment in half, and draw a perpendicular through the dividing point, not bringing it to the chest line 6 cm, and 12 cm to the hip line, this perpendicular is the midline of the dart. We connect points 6 and 12 with the points of the tuck solution T 3 and T 4.

Refinement of the waist line and the bottom line of the shelf... From point T 1, we put down 1 cm, the resulting point will be connected with a notch along the waist line along the side cut, observing a right angle at point 1 cm. Down from the point H 1, we also set aside 1 cm and connect it with a smooth line with the point of the bottom line along the side cut, while the angle at the point 1 cm should be straight.

Building a tackle tuck on a shelf... Subtract 1.5 cm from the value of the segment G 1 G 5, postpone the resulting value to the left of the point 1 cm along the new waist line and put the point T 5 (1T 5 = G 1 G 5 -1.5 = 8.5-1.5 = 7cm ). Let's connect points T 5 and G 5.

Along the new waistline to the left of the point T 5, we postpone the size of the solution of the front dart and put the point T 6 (T 5 T 6 = 3.3 cm). Along the line Г 5 Т 5 downwards from the point Г 5 we postpone 6 cm, we connect the resulting point with Т 6.

We divide the segment T 5 T 6 in half, and from the point of division we lower the perpendicular, not bringing it to the waist line 12 cm. Now let's connect point 12 with points T 5 and T 6.

This completes the construction of the shirt design.

If the shirt model has a button fastener, then the shelf must be extended along the neckline and the bottom line by the same distance - 1.5-2 cm and draw a new cut line for the shelf. The resulting line is the half-line line, and on the middle line there are buttons on one part of the shelf and buttonholes on the second part.

Clasp sections can be processed in several ways:

Stitching bar ,

The width of which is twice the width of the half-strip, the length of the strip is equal to the length of the ledge along the half-strip line, while the upper cut of the strip repeats the cut of the neck of the ledge along the entire width of the strip.

One-piece plank ,

Its configuration is completed by extending the bottom line of the shelf by twice the width of the half-nose, and then a vertical line is drawn upward from the resulting point. The line of the neckline on the bar is drawn symmetrically to the neckline of the shelf relative to the half-line. When sewing a shirt with a one-piece strap, the strap itself is bent along the half-line to the seamy side of the product.

Supate clasp

It is a hidden clasp, buttons in such a clasp are hidden and are not visible from the front side of the product. The configuration of such a fastener is completed from a one-piece strap, extending the bottom line of the product by a length equal to twice the width of the strap. As a result, three widths of the plank are obtained along the bottom line, a vertical line is drawn up from each width. The line of the neck of the fastener is drawn symmetrically relative to the line of the first plank. Along the half-line of the shirt, the fastener is bent to the seamy side, along the next vertical line, the clasp is bent, and along the next vertical line, the fastener is folded back to the seamy side and the cut line of the shelf (on the fastener) is stitched from the seamy side of the product. The supate clasp is built on only one part of the shelf, on which the buttonholes are located, and only a one-piece strip is built on the part with buttons.