Wet felting workshop: Felting darning socks. How to Felle Cozy Socks Felted Socks Pattern

Fur is a material that is multifaceted in its properties and capabilities, it can make like a small toy and cozy socks, which you, as a fashionable and practical gift to loved ones. Socks can be made to any size, length, color, additions, lace, ribbon embroidery. The main thing is that the child's feet heats up and is surrounded by care.

What you need

- 40 G Wool;

- Ruler;

- Laundry soap;

- Mosquito Net (Tulle);

- Bubble wrap (2 pcs - 50 * 50 cm);

- Rolling pin;

- Sponge.

Management

- Prepare a soapy solution. Coarsely grate a bar of soap with 2 liters of boiling water. Stirring regularly until the soap is completely dissolved, insist for about 2 hours, the solution should thicken.

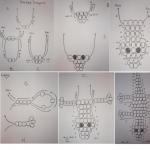

2. Make 2 socks templates out of foil. Then start the fur at the top of the bootleg.

3. In the process, pay attention to the thickness of the strand of hair, alignment and position of the hand. From the middle of the lower leg, continue, the distribution of the coat is a dark shade, until you have covered the entire surface of the cut.

4. Extend the second layer, set the pink curls upright, and a dark corner at 90 °. Also, at the bottom border, lay another row of yarn perpendicular to the hem.

5. Cover the workpiece with tulle (lattices) and moisten the wool with a sponge (through the tulle) with warm soapy water. Then iron for about 1 minute.

6. Remove the lattice, Fold in the top edge 1 cm, Fix, smoothing the wool vertically. Now they cover the part of the air bubble film, turn to the other side so that the film is on the bottom.

7. Wrap all the reasons for the wool structure, stretch, folds and grooves. Repeat the steps above, showing first hot pink yarn and then darkness. For the second layer, repeat the operation with the mesh, blotting the parts in soapy water.

8. Covers bubble wrap, apply rolling pin with light pressure in 2 directions. Follow the steps outlined for a roll with a rolling pin on the other side. Later, after rolling the product onto a rolling pin, roll the "role" of the "from yourself to yourself" movement, approximately 10 times. Repeat this step, four times, in different directions: up, heels, soles.

9. Remove the tape by carefully ironing the wool around the edge. Add some soap to slide your hands over the treated item. Repeat the operation in the same way on the other side, transforming the semi-finished product.

10. Remove the template, onto the future sock on your hand and go through the folds, even all kinds of wrinkles. Pull the product slowly during the procedure, if necessary.

11. Repeat the ironing steps, only without the rolling pin, you roll 50 times. Consecutively roll the sock into a tube in 4 directions and roll it onto the table 30 times on each side. Guides its edge regularly. Gradually the yarn starts to shrink. Prepare a second sock.

12. In the final ruler, check the size, sock and include the required size by doing the following: remember a little, the product, knead like a dough, roll like a ball, rub per film.

13. Then even, rinse so that there is no soap left. Click not to rotate. They form socks, examples on the leg, let dry. Decorate the finished socks as you like.

They are knitted from woolen threads, which are not intended for washing in a machine (Superwash), but only FOR HAND WASHING. Threads can be either 100% wool or wool with an artificial admixture, I repeat, the main thing is that they should have a "Hand wash" badge (maybe threads that cannot be washed at all, but I have never seen such threads).

There are special threads on which it stands that they are for felting (filzen), but ordinary woolen threads are also suitable. The yarn can be any, even home-spinning, even factory-made, even natural, even dyed.

The thicker the threads intended for thick knitting needles, the thicker the finished product will be. I like threads for knitting needles number 8, there are also threads for knitting needles N 6 and 7, I also knitted one pair from N 6. For knitting needles N 9 or 10, I have not yet met the thread.

After washing, the products shrink 30-40%, to find out, you need to knit a test piece, measure, wash and measure again, we will see shrinkage. But this is terribly dreary for me, I knit at random according to the table (see below), how it comes out, so it comes out, it suits someone; 0).

Basically, it is everywhere that they felted at 40 ° C, but at this temperature, only one pair of slippers took on the required size, the rest had to be scrolled 2-3 more times with hotter water. For some, 50 ° was enough, for some as much as 60 °. So now, at my own risk and peril, I wash immediately at 60 °. It may well be that my machine does not heat water well, I don’t know, so we have to try.

Threads of the same company and of the same grade and name, but in a different color, are felted in different ways, most likely it depends on the paint, they are of different composition, the wool can be bleached for some colors, I don’t know, but apparently they have different effects on wool ...

It's better to wash with something hard, I've already read that it's good with jeans. The machine should not be tightly packed, socks should be loose. They recommend washing several pairs at a time and throwing several tennis balls with them, they beat and rub our blanks, which helps the socks to fall off. I washed with balls, when I knitted several pairs, collected 3 pairs in the machine, but now I do not knit so much, and I want to see the result sooner, so I washed, for example, with 2 sauna towels, ordinary bath towels, and threw in balls too.

The program should be set to the most ordinary, not "light" one, add a little powder, no rinse aid is needed. After washing, stretch the socks into the correct shape, it is best to pull on the desired leg and you can even walk or sit in them so that the shape is strengthened. Cram in a newspaper, then it will keep its shape while drying. Many people tuck sneakers into wet slippers that are 2 sizes smaller than the desired size. When drying, they shrink a little more, keep this in mind, so cram newspapers tightly or, as I said, dry on your leg (my youngest wanted to dry his own so much, that's why they probably became the nicest and most beautiful ones)))).

I forgot to write right away, I'm editing.

The socks come out terribly slippery and, I think, they wipe quickly too, so I smear my foot with liquid latex, I buy it in the store where the threads are. Dries quickly, not hard, not slippery.

Well, we've passed the theoretical part, let's get to work.

We will need:

woolen threads intended for hand washing in not hot water;

2 long needles or needles on the line;

5 knitting needles for knitting socks;

a thick darning needle with a large hole or a large hook for assembling the workpiece.

On long or circular knitting needles, dial the number of loops required for your foot size (line 2 in table 2) (line A in table 3).

We knit the required number of rows (in table, page B), one front row, the next purl, etc.

now we collect 2 loops, divide by 4 knitting needles and knit round like normal socks. How many closed rows to knit can be seen in the table. p. S.

Close the sock by knitting the last 2 loops together on each knitting needle. When there are 2 (or 2x2 and 2x3 loops) left on each knitting needle, cut the thread and pull it into the loops and tighten.

Sew the thread with a needle or crochet. Sew on the back of the heel.

Example on foot size 37, for knitting needles number 8, this is the blue table:

We collect 32 loops on round or long knitting needles, we knit 32 rows, alternating the front row and the purl row. We throw in 2 more loops, we get 34 loops, divide them into 4 knitting needles: 8, 9, 8, 9 loops. Knit 24 rows.

Here I have a snag, because I can't figure out whether to start cutting after 24 rows, or the shortened rows are included in these 24 rows. I tried this and that, but the threads set in different ways and I still did not understand how best and how it should be.

We begin to cut the last two loops on each knitting needle in each row and get 2,3,2,3 loops at the end on the knitting needles. We stretch the thread into the loops and sew.

Sock size 38:

The first line in the tables shows how many 50g balls of thread are needed for one pair of slippers.

D-last line is the length of the finished socks after washing in cm.

PINK thread and knitting needle chart N 6

BLUE thread and knitting needle chart # 8.

Before washing, size 40 and 37, the threads for gray socks were 100% wool, unpainted, natural color, for knitting needles 7 or 8, I knitted with 8. Reds were also 100% wool, but special. for felting, a little thicker thread and for knitting needles 8..

Have you ever wanted to have warm slippers that will keep you warm in the most severe frosts? Your attention is offered a detailed master class on felting knitted socks in a lazy way, or rather, in a washing machine. This master class details the formulas for calculating knitting density, taking into account the shrinkage of woolen yarn after felting. Preliminary calculations in this method of felting play a key role, if as a result you do not want to get children's booties instead of men's slippers. It should be noted that only wool yarn should be felted; various synthetic additives are not allowed.

Materials (edit)

Yarn Our village 01 natural color (90 g / 170 m, 100% wool), needles 4.5 mm.

Before you start working on the socks themselves, you need to knit a couple of swatches. Since it was difficult to determine which knitting method was preferable, I knitted three patterns on 3 mm needles: front stitch, pearl stitch and garter stitch. For samples that have not yet been processed, it is necessary to determine the knitting density for future socks:

18 p. And 23 p. = 10 x 10 cm with front stitch

16 p. And 27 p. = 10x10 cm pearl knit

16 p. And 32 p. = 10x10 cm garter stitch

After that, I threw them into the machine, chose the "cotton" mode for the washing machine, set the temperature to 60 degrees and washed these samples. We look at the result, the sample made with the front satin stitch has the following dimensions: 8 cm horizontally and 7 cm vertically, the total knitting density has changed and now is 23 p. And 33 r. Total horizontal shrinkage is 22% and vertical shrinkage is 30%.

The sample bound with pearl viscous shrinkage least of all, its density is 20 p. And 34 r. The structure of the canvas has also undergone the smallest changes. Let's move on to the garter stitch pattern. It turned out to be the densest and thickest than the others. The density after felting is 21 points and 38 rubles.

The most successful was the pattern with the front satin stitch, so we will knit socks in this way. Let's start with the calculations: the shrinkage factor is 18 p. / 23 p. = 0.78. The ankle girth is 23 cm, which means that 23 cm will ultimately be 52 stitches (23 cm * 2.3 sts = 52 stitches), we divide this number of stitches by the coefficient obtained: 52 sts / 0.78 = 66 stitches are needed for the initial row.

So, we collect the calculated number of loops and knit socks in the usual way. I knitted for size 36 feet. Here's what happened. To say that these socks look huge is nothing to say. After both socks are tied (by the way, exactly one skein of yarn went to one such sock), it is necessary to carry out preparatory work. Let's take a few bags, the bags are not colored, otherwise you can ruin the socks. The bags are needed so that the seamy part of the socks does not fall together during felting. We put the bags and sew them up with ordinary cotton thread in a neutral color.

That's all, let's go play. We set the parameters of the washing machine described earlier, load the socks and start the cycle. After the machine has finished washing, we take out our socks and see that now these are solid homemade felt boots. The result exceeded all expectations! A photo of ready-made socks was published at the beginning of the master class.

If, the first time, your socks do not fall to the desired size, then you should not despair. To correct the situation, it is enough to repeat the wash cycle with the same parameters.

Happy lazy felting in the washing machine!

There were holes in the warm, soft Mongolian woolen socks. She twisted them, twisted them in thought, from which side and with what tools to get close to them ... I remembered that I have a certain amount of wool for felting. Well, in reserve. Why not conduct another experiment and start your first steps in felting with darning socks? I tried it, I'm very happy with the result! I share with you!

So, there are socks that require darning, wool and a felting needle, and a foam sponge. Let's get started.

Turn out the sock, put a sponge on the floor, and smooth it out.

We tear off small strands of wool and cover the hole with them.

We begin to roll the wool with a felting needle.

Continue ...

It's already beautiful. This is the wrong side.

We turn it out. Such a fluffy turned out. Here I put the sponge in again and pryvivali already from the front side. If you feel that in some place it is thin, add wool and roll on.

I wet my sock, lather.

At first I do not rub hard, then I increase the pressure.

I turn it out and repeat everything from the inside out.

Checking. The hairs have not yet rolled up, we must continue.

I rinse well and dry.

Finished inside heel ...

and from the front.

The patch turned out to be soft, dense, as it was!