How the Airbus A380 airliner is made. Paper model

The Airbus A340 (Russian Airbus A340) is a long-range four-engine wide-body jet passenger aircraft developed by Airbus SAS. In general, it is similar to the A330. The Airbus A340-600 for 2006 was the world's longest passenger aircraft with a fuselage length of 75.3 meters.

The A340 aircraft project (originally TA11 (TA - twin aisle - "wide-body")) was first presented to the public in 1981 in the November edition of Air International magazine. The number also indicated the expected characteristics of the future aircraft. In September 1982, the consortium announced that the new aircraft would have an overall airframe design.

The A340 development program was launched in June 1987. The goal is to create a long-haul “brother” for the short-haul A320 and the medium-haul A300. At that time, the twin-engine airplanes of Airbus were inferior to the four-engine Boeing 747 according to the ETOPS standards: during the flight, twin-engine aircraft should always be at a minimum distance from a possible emergency airfield in the event of a failure of one of the engines. In this regard, the A340 was in the Airbus family a fundamentally new aircraft designed specifically for intercontinental flights.

Print the downloaded PDF files to a printer.

Cutting out

Step 1 Before you start cutting out parts, free your workspace from unnecessary things and paper so that you do not lose small details.

Before cutting out the parts from the sheet, lightly press the folds with a ballpoint pen with a dried core or something similar. The main thing is not to scratch the surface of the paper.

This will help you make the curves along the line more neat.

Step 2 Cut each piece individually, leaving sufficient margin around the edges.

Step 3 After you've cut out a piece, carefully write the number on the back so you can keep track of which pieces you have.

Step 4 Carefully trim off the extra margins from each piece.

Step 5 Always cut along the outer edge of the black line. Then, when you start assembling the parts, they will go well with each other.

Folding parts.

Use a ruler when bending in straight sections. For an inner fold, place a ruler along the fold line. Then lift the paper up and press it against the edge of the ruler.

External bend. To make the outer curve, place the ruler over the edge of the table and place the template on top. Carefully align the fold line with the edge of the ruler and fold the paper downward.

Curved parts To give the detail a natural bend, you need to rub it against the corner of the table. This will make gluing easier.

You can also wrap the part around a pencil, and then unfold and give the parts the desired rounding radius.

Gluing

Waiting for the glue to dry completely is key to ensuring good build results.

If you get glue on your hands, you will ruin the models, so make sure you have clean hands at all times and wash your hands right away, or dry them off with a damp towel.

Step 1 Apply colorless and quick-drying glue. Optimally - PVA. Squeeze a small amount of glue onto a piece of cardboard or plastic.

Step 2 Then, using a strip of thick paper or cardboard like a spatula, scoop up the glue. Remember to only apply glue to one side of the trowel.

Step 3 Apply a thin layer of adhesive evenly to the bonding valve with this trowel.

Step 4 Hold the parts firmly in the bonding area until the adhesive is completely dry.

Step 5 Assemble the parts individually and wait until they are completely dry before assembling all models!

). I would like to say about this aircraft that it is an example of outstanding engineering thought of the last century. At the time of its creation in 1969 Boeing 747 was the largest, heaviest and most spacious passenger aircraft. Despite the initial skepticism of specialists towards the aircraft, he held a leading position in passenger aviation for almost 35 years.

We warn you right away that the proposed model of the plane (read also) will not be so easy to make, you may need several days, but this lesson will definitely be interesting and informative.

To make a Boeing 747 model, we will need the most affordable and common material for crafts - paper (a sailboat made of paper), and, of course, we will need scissors and glue.

First, you will need to print the sweep diagrams (Figures 1 to 13) on a color or black-and-white printer (for this, you need to contact your parents or older brothers and sisters for help). After that, cut out all parts of the plane and, following the instructions (Figures 14 to 26), glue them. The main thing is to act strictly according to the instructions, sequentially performing all the stages of assembling the model.

Let's get started!

Boeing 747 airplane parts diagrams made of paper

This was the last drawing with a diagram of the aircraft parts. Now the figures will show instructions for its assembly. Do not be intimidated by foreign words, everything is quite simple and clear here. If you have any difficulties, ask your parents for help.

Instructions for gluing model aircraft

Model for your collection.

Airbus A320 of Vietnam Airlines - the state airline of Vietnam.

Model for your collection.

Model for your collection.

AIRBUS A340-300 Air Thahiti Nui. Country: French Polynesia. Long haul flights from Papeete.

Print on a printer, on A4 sheets of matte thick paper, cut and glue.

Model for your collection.

Model for your collection.

Airbus A340 (Russian. Airbus A340) is a long-range four-engine wide-body jet passenger aircraft developed by Airbus SAS. In general, it is similar to the A330. The Airbus A340-600 is the world's longest passenger aircraft with a fuselage length of 75.3 meters.

Print on a printer, on A4 sheets of matte thick paper, cut and glue.

Model for your collection.

Model for your collection.

Airbus A320-200 of the Japanese airline StarFlyer.

StarFlyer operates a fleet of 4 modern Airbus A320-200 aircraft.

The planes have an unusual black and white design developed by Flower Robotics Inc.

Print on a printer, on A4 sheets of matte thick paper, cut and glue.

Singapore Airlines uses Airbus A380 for flights from Singapore to Sydney, London (Heathrow Airport), Paris (Charles de Gaulle Airport), Tokyo (Narita Airport), Zurich, Melbourne, Hong Kong, Frankfurt, since March 2011 to Los Angeles ...

Singapore Airlines uses Airbus A380 for flights from Singapore to Sydney, London (Heathrow Airport), Paris (Charles de Gaulle Airport), Tokyo (Narita Airport), Zurich, Melbourne, Hong Kong, Frankfurt, since March 2011 to Los Angeles ...

Airplane model.

Airplane model.

Replica of the Air France Airbus A330 Flight 447, which suffered the largest plane crash in the history of Air France on June 1, 2009.

Print on a printer, on A4 sheets of matte thick paper, cut and glue.

The giant double-decker Airbus A380 is the largest passenger aircraft in the history of world aviation, with a maximum capacity of 853 passengers in a single-class layout. The first copy was delivered to the customer in 2007, more than 110 machines have been built to date! Today I want to show the A380 assembly line at the plant in Toulouse, the scale and dimensions of what I saw are impressive ... Well, for a big plane - big photos in the reportage!

Many spotters, and not only them, find the plane aesthetically unattractive. I strongly disagree with this statement, moreover, I consider it especially beautiful and elegantly heavy. The slow-taking off A380 is beautiful!

Now let's go to the factory ...

This is a diagram of the location of production facilities at a plant in the town of Balagnac near Toulouse, orange is the assembly shops of the A380.

Each A380 is made up of about 4 million individual components and 2.5 million parts, manufactured by 1,500 companies in 30 countries.

The main elements of the A380 fuselage cannot be transported by air, so they are transported by sea and river on specially adapted barges, and then twice a month by cars - this is called a "night convoy".

Especially for this aircraft, Airbus has developed a unique logistics system, which involves sea, river, air and road transport. From the town of Lisle-Jourdain, about 30 km from Blagnac, at exactly 22:00, the night convoy begins to move at a speed of 15-20 km / h, so as not to interfere with traffic - six trailers, which accommodate all parts of the aircraft, leave in two hours. the way to the final point - the final assembly line in Blagnac.

Fuselage sections with a diameter of 7 meters are driven straight through the narrow streets of the town. But this is the only possible and most optimal point of delivery of the liner elements to the plant.

At the first station, the fuselage sections are assembled and connected to each other.

Then the wings and vertical stabilizer are mounted:

The wing area of the A380 is 845m2, which is 54% more than that of the Boeing 747-400!

And it's not just a tail ... it's FIVE giraffes! :)

Preparation of engine pylons:

The aircraft is assembled, the passenger compartment and cockpit are installed in the following positions:

Each of the main landing gear is capable of withstanding a load of up to 260 tons, which is equivalent to the weight of 200 cars of the Golf class.

And finally, the last assembly station, where the installation of engines and passenger seats is carried out:

The A380 can be equipped with two types of engines: Rolls-Royce Trent 900 or Engine Alliance GP7000. Only two of the four engines are equipped with thrust reversers.

Reducing noise levels was an important design requirement for the A380, which was also partly reflected in the engine design. Both types of engines allow the aircraft to meet the QC / 2 on departure and QC / 0.5 on arrival limits set by London Heathrow Airport.

The A380 is the most economical aircraft in its category. This is the only long-haul liner that consumes less than 3 liters of fuel to transport a passenger per 100 km (typical layout of 525 seats)

The total area of the A380 cabin is 554 m2. Two full decks: main deck - the widest passenger compartment in the world (6.5 m); the upper deck is a full-fledged salon of a wide-body aircraft (5.8 m). The air conditioning system of the aircraft is equipped with the most modern filters that ensure uniform air supply to all parts of the aircraft. The air in the aircraft cabin (with a volume of 1570 m3) is completely replaced every three minutes! The A380 has the quietest passenger cabin in the history of world aviation, I was convinced of this personally on the way from Frankfurt to Singapore.

This A380, presumably, will be transferred to a private customer. And behind it is the A300B, the first aircraft produced by Airbus. This aircraft revolutionized civil aviation in the 1970s, becoming the first wide-body twin-engine aircraft.

The circular structure on the right is the static test area of the motors, along the circle there are barriers that limit the distribution of the sound wave.

To date, more than 110 A380 aircraft have been produced, an average of 2.5 aircraft are produced and delivered to customers every month. The backlog for orders is 160 more boards! At the moment, the A380 is in service with 20 airlines.

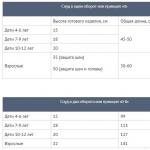

Here are some interesting statistics for replacing B777 / B747 on some flights:

Emirates has the largest A380 fleet:

Five A380s were built for demonstration and testing purposes. The first A380, serial number MSN001 and registration F-WWOW, was unveiled at a ceremony in Toulouse on January 18, 2005, and first flew on April 27, 2005. Here is the very first A380:

A rare word origami, it would seem, has nothing to do with our favorite pastime from childhood - launching an airplane. Nevertheless, the art of folding this figure also came to us from Japan. There they learned how to make origami toys 2000 years ago, and an airplane in the East was embodied in a beautiful and complex form of a kite and the person who made these paper structures is in a special account.

How to make a large paper plane

This method will allow even the most inexperienced craftsman to make large models of "Tu" -shek, "Airbus" and fighters. Moreover, at least a large album sheet or a sheet from a magazine can be used for these purposes. You can even take a roll of wallpaper if you wish: the main thing is to follow the technology.

So, take a large piece from the scrapbook and fold it in half along a vertical line. Unfold the sheet and fold the top two corners towards the center. It remains to fold the sheet on both sides to the very middle and spread the wings. Airbus is ready to fly!

How to make a paper airplane: instructions

The most popular is the traditional folding type, which includes only 6 folding steps. To make an airplane, you only need a sheet of cardboard or A4 paper from a regular school album.

- First of all, bend the left (right) edge and straighten the sheet. So even a child will understand where the middle is.

- In the second step, we fold the corner, so that it completely touches the fold in the center of the piece, and we begin to bend the right corner from above.

- The third stage - you need to bend the corner formed near the central fold.

- The task of our actions at this point is to ensure that the sides of the corners do not reach a few centimeters to the fold in the very center.

- We are almost done: for now, just bend the tip. It has to hold back the folded corners.

- And finally, the last sixth stage - we fold the fake in half, and again with the side to the main fold. We launch our fighter into the air!

Have a great flight!

Attention!

This technique is considered the most common and children begin to learn how to make airplanes from it. .

How to make a paper fighter: video

You can try to make something unusual from the sheet, for example, the cult aircraft from America Stealth (in English the name sounds like Stealth). The video, which is presented in English, is nevertheless understandable even to a person without knowledge of the language. The explanations are light and simple. The curves are clearly illustrated with the handle.

This aircraft differs from previous models in that it does not fly. But the craft is so beautiful and effective that it will surely become a part of your favorite war game. For manufacturing, prefer colored paper, which will make the model winning and bright.

A paper airplane that flies for a long time

A jet with a long flight is the dream of any child. At the same time, some masters know why the flight time and distance depend, and from time to time they demonstrate their skills by making “long-flying” models.

What secrets can you remember to make your plane fly long and beautifully?

- The main thing in any model is a neat tail. The better the folds in the model, the longer it will last in the air. Wrong Tail - Don't expect the plane to hover.

- Try to make origami symmetrical: then the cardboard plane will not collapse and will last much longer in the air.

- Bend your wings slightly: this secret also affects flight duration. Some guys who know how to fold their wings correctly become the winners of airliner competitions at school or in the yard.

- The leaf should be thin: then the craft will lower more slowly and will hold out further in the air.

Just a few tricks - and your craft will become the best, will help you gain fame as the best and most experienced "pilot".